The industrial visit to Titan was organized by the Luxury Management department of MBA ESG to provide students an inside look at the making of luxury and premium watches along with other umbrella brands by Titan Watches. It was also intended to provide insights into the watch industry in India.

Titan Watches was started in 1984 as a joint venture between Tata Group and the Tamil Nadu Industrial Development Corporation. The company brought about a paradigm shift in the Indian watch market when it introduced its futuristic quartz technology, complemented by international styling. Today, Titan stands as the 5th largest integrated brand watch manufacturer in the world.

The Visit

Mr. Salvem from Titan, our speaker for the visit, explained key concepts related to the watch-making process. Students learnt,

- How case pressing is done

- How cases are trimmed into different designs

- The materials used for watch-making based on the price range

- Polishing, via diamond cutting and shaping

- Production elements

- Manufacturing of the tiniest parts of the watch

- Packaging and the company’s presence in Indian markets

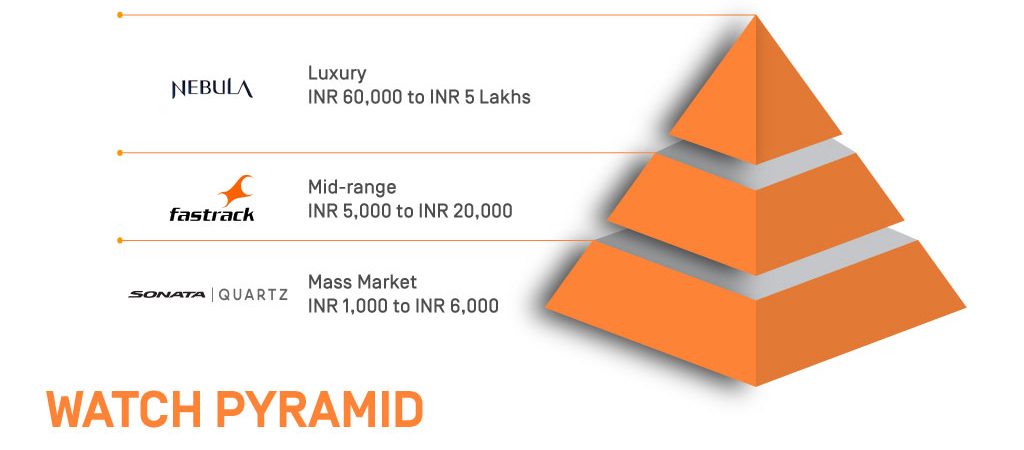

Students discovered what characteristics classify a watch as luxury, mid-range, and mass market.

Students were taken through the complete manufacturing life-cycle of a watch.

- Case-Making and Cutting: This process involves the shaping and sizing of dials of different materials including brass, copper, and platinum.

- Manufacturing of Different Parts: Every single part, even the tiniest of parts, which could only be seen through a microscope, were manufactured in the factory itself.

- Shaping of the Dial: A separate department does the shaping of dials.

- Assembling and Testing of Parts: Their assembly warehouse is spread over an area of 40,000 sqft. Mr. Salvem explained that women were mostly assigned the task of assembly as they are considered to be more patient.

- Quality check: Titan provides the highest quality watches due to a rigorous quality-checking process. State-of-the-art machines such as CMM, Videograph Measuring Machine, Form Tester, Roughness tester, Height Master, etc. are used for this purpose. As such, this area was restricted to visitors.

The Watch industry is intricate and complex, just like its creations. It was quite a productive outing for our students, who also thoroughly enjoyed the visit.